Digitalisation & Analytics for Powder Coatings

Digitalisation & Analytics for Powder Coatings

Condition Management in H², Biogas and Reciprocating Compressors

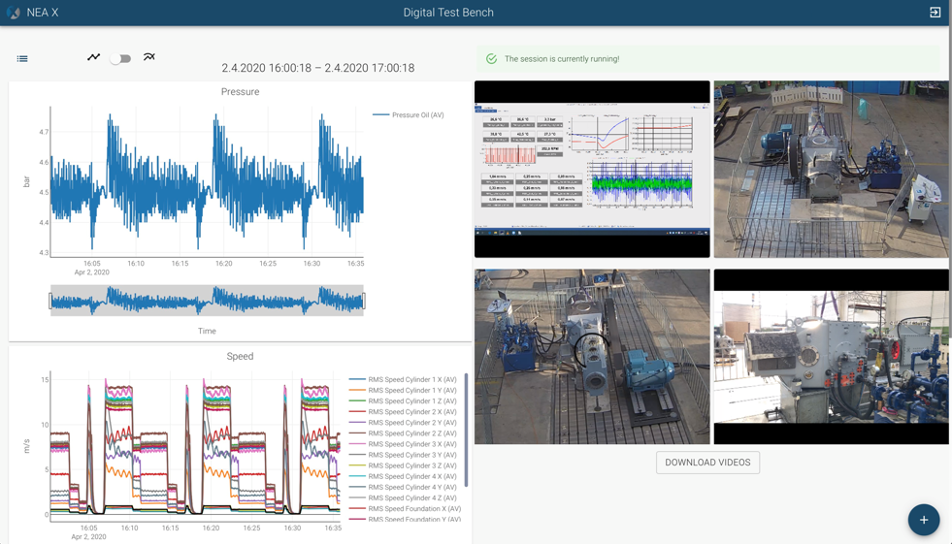

Immersive digital testbench experience

Production Excellence for Manufacturing Processes

To amalgamate Service Excellence with Digital Expertise, NEA X together with NEAC offer NEAC CONDITION MANAGEMENT – a real 360°-solution from Digital Service Strategy to Maintenance Execution with customized service levels .

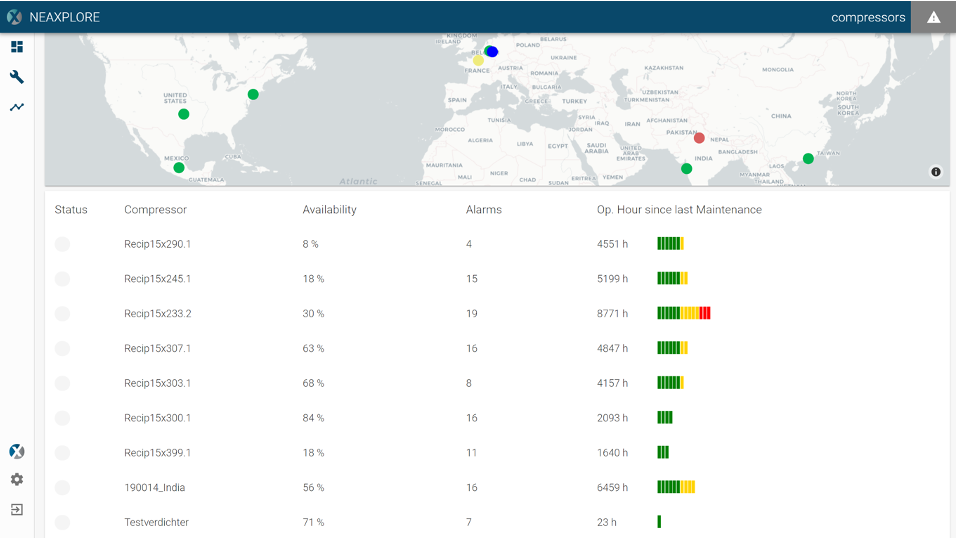

XPLORE is your platform solution of choice if you like to support your engineers in monitoring, analyzing and diagnosing machine performance of critical assets.

Built on the extensive knowledge of NEAC engineers, it allows to assess the health of compressor systems at any time from anywhere.

Cost-effective data processing and analytics combined with optimized hardware results in an affordable solution with immediate impact and quick RoI.

Quick access to real-time data or to historical information, machine reports, KPIs gives insights almost on the fly.

Based on slow data, visualize and analyze parameter trends and critical developments for risk assessment and predictive maintenance.

Powerful Alarm Management supports the handling of hard and soft alarms remotely. Set in-application alarms for detailed supervision of parameters.

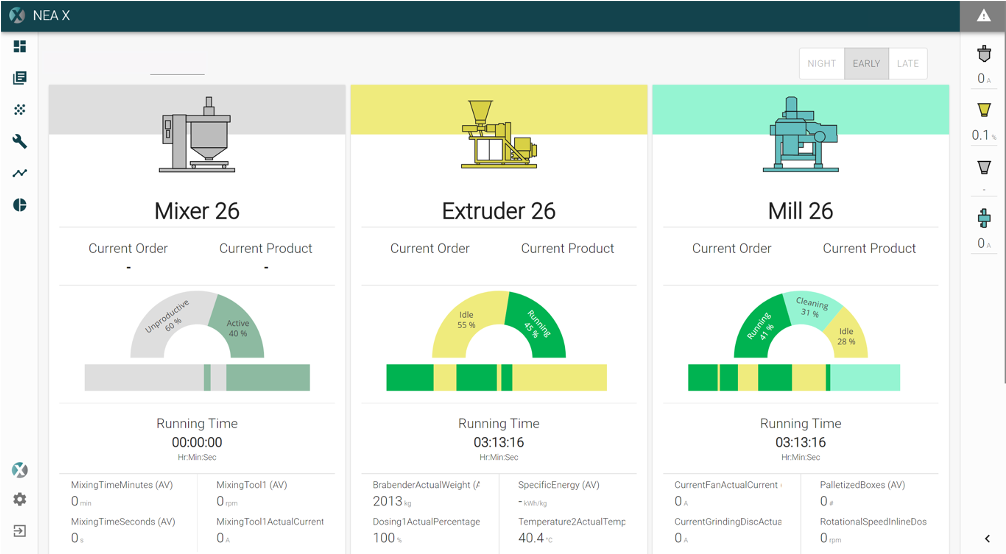

Track your products along the entire production process – from raw material to packaging, seamlessly, for any batch, with a single solution.

Analyze availability and throughput and take according actions

Trace your products and batches, identify cycle times for improved production scheduling

Automated machine parameter setting allows identical production conditions for each batch of every product

Machine performance analysis allows for remote monitoring of potential sources of failure

Not all your challenges can be tackled with a standardized system. Together with you we are creating ways to make you even better.

Is it about projects to support your employees at the core of your value chain in their daily work, or about the automation of sub-processes? You would like to be able to be faster in decision-making and would like to base it on proven data?

We find solutions for demanding challenges on your shopfloor covering all levels of IT. In individual development projects visualization-, analysis- and control software with interfaces to upstream or downstream systems is fitted to your individual landscape.

What drives us is our passion for data, machines and insights supporting decisions and actions that have a measurable impact for our clients‘ operations.

In everything we do we are truly dedicated to our clients‘ needs and their targets.

We are strongly aware of our heritage. Thus, we always combine the knowledge of a plant engineering company with our digital expertise creating solutions that are providing spot-on results through intuitive and hassle-free handling.

We want to establish our platform solution as a crucial element in our clients‘ operations. When it comes to insights from machine data, we want to be the undoubted partner for our clients striving for digital excellence at the core of their value chain.

Agile. Solution. Experts. We are taking NEUMAN & ESSER GROUP’s claim very seriously and bring in the knowledge from a broad range of backgrounds with proven experience.